11-Apr-2024 by

Handmade PapersHow does handmade paper differ from machine-made paper in terms of quality and characteristics?

Exploring the Quality and Characteristics of Handmade Paper versus Machine-Made Paper

Introduction

Paper, an essential medium for communication and expression, has evolved over centuries, with diverse methods of production yielding a plethora of paper types. Among these, handmade paper and machine-made paper stand as prominent representatives, each possessing distinct qualities and characteristics. This comprehensive exploration delves into the intricate differences between handmade paper and machine-made paper, shedding light on their respective qualities, production methods, and applications.

Historical Context of Papermaking

The origins of papermaking trace back to ancient civilizations, notably China and Egypt, where early forms of paper were crafted from plant fibers such as papyrus and mulberry bark. Over time, papermaking techniques spread across the globe, undergoing refinement and innovation in various cultures. Handmade paper emerged as the traditional method, characterized by meticulous craftsmanship, while the Industrial Revolution ushered in the era of machine-made paper, revolutionizing mass production.

Production Processes: Handmade Paper

Handmade paper production embodies a labor-intensive, artisanal approach, rooted in tradition and craftsmanship. The process typically begins with the selection and preparation of raw materials, which may include cotton, linen, hemp, or other plant fibers. These fibers are then pulped, either through mechanical or manual methods, to create a pulp mixture. The pulp is then dispersed in water and poured onto a screen, where it is manually agitated to form a uniform sheet. The wet sheet is transferred to a felt mat, pressed to remove excess water, and air-dried, often under controlled conditions. Finally, the dried sheets are inspected, trimmed, and finished as per desired specifications.

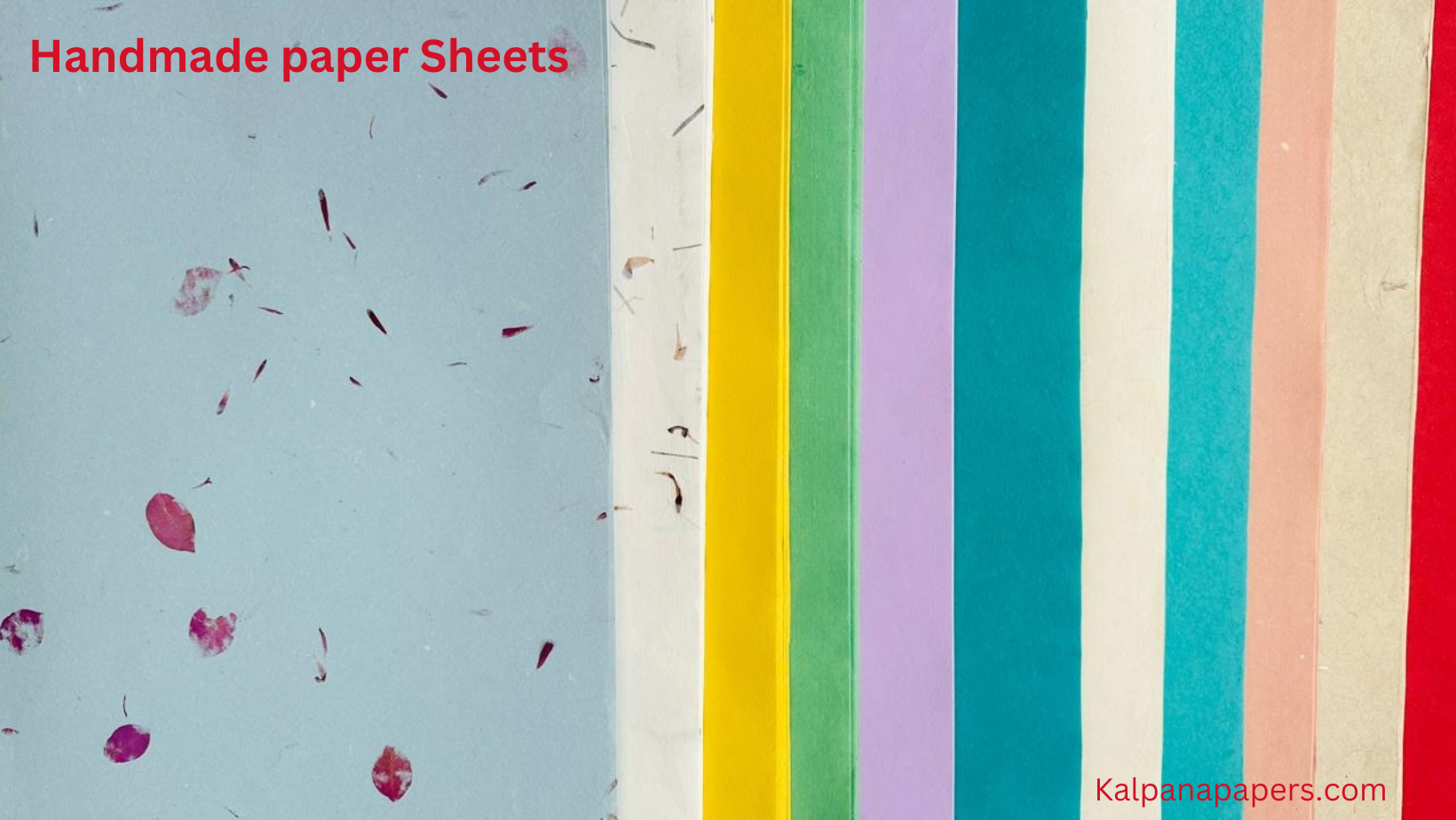

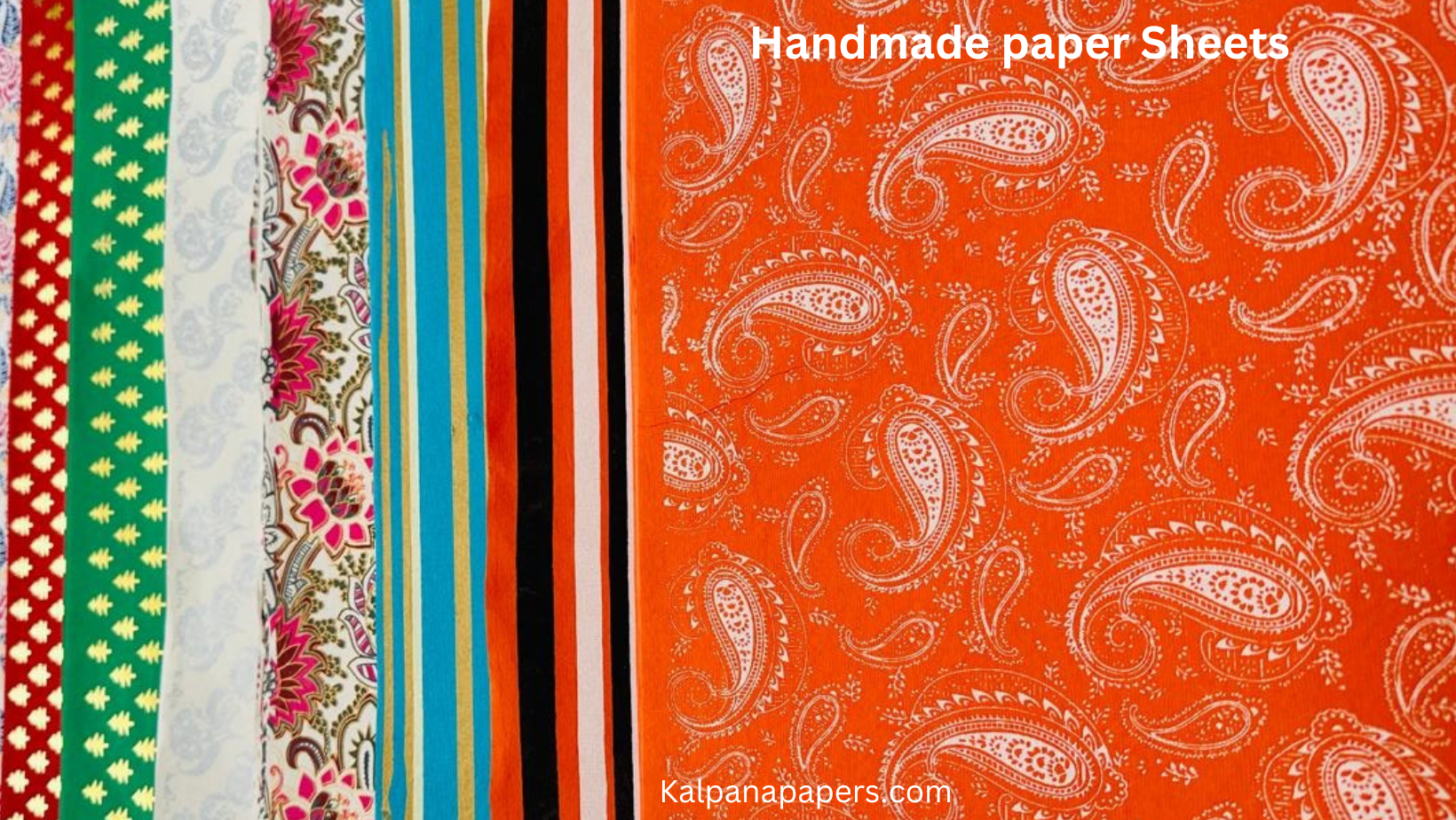

Characteristics of Handmade Paper

Handmade paper exhibits a plethora of characteristics that distinguish it from its machine-made counterpart. Its texture is often irregular and tactile, imbued with unique fibers and inclusions that lend it a distinct aesthetic appeal. Variations in thickness, opacity, and surface finish contribute to its individuality, making each sheet a work of art in its own right. Handmade paper's strength and durability may vary depending on factors such as fiber type, sheet formation, and pressing techniques, but its inherent charm lies in its imperfections and organic nature.

Production Processes: Machine-Made Paper

In contrast, machine-made paper production epitomizes efficiency and standardization, harnessing modern technology to streamline the manufacturing process. Wood pulp, obtained from trees such as spruce, pine, or eucalyptus, serves as the primary raw material for machine-made paper. The pulping process involves mechanical or chemical methods to break down the wood fibers, resulting in a pulp slurry. This slurry is then fed into a paper machine, where it undergoes a series of treatments including refining, forming, pressing, and drying. The continuous operation of the paper machine ensures consistent quality and high production volumes, catering to diverse industrial and commercial applications.

Characteristics of Machine-Made Paper

Machine-made paper exhibits characteristics distinct from its handmade counterpart, reflecting the precision and uniformity inherent in mass production. Its surface is typically smooth and even, owing to the mechanized forming process that imparts a consistent texture to each sheet. Machine-made paper offers superior strength and durability compared to handmade paper, owing to the controlled manufacturing environment and standardized processing parameters. These qualities make it well-suited for applications requiring reliability and performance, such as printing, packaging, and industrial uses.

Quality Comparison: Handmade versus Machine-Made Paper

When evaluating the quality of handmade paper versus machine-made paper, several factors come into play. Handmade paper excels in terms of artistic expression and individuality, offering a unique canvas for creative endeavors. Its tactile qualities and aesthetic appeal make it highly sought after by artists, designers, and enthusiasts who value craftsmanship and authenticity. Machine-made paper, on the other hand, excels in terms of consistency, reliability, and affordability, making it indispensable for commercial and industrial purposes.

Applications and Uses

Handmade paper finds application in a myriad of artistic, cultural, and decorative pursuits, ranging from fine art prints and stationery to bookbinding and mixed media collage. Its versatility and charm make it a preferred choice for bespoke projects and luxury goods, where quality and aesthetics take precedence. Machine-made paper, with its wide availability and cost-effectiveness, caters to diverse sectors including publishing, packaging, advertising, and office supplies. Its uniformity and performance characteristics make it indispensable for mass production and commercial applications.

Environmental Considerations

In an era marked by growing environmental awareness, the choice between handmade paper and machine-made paper carries implications for sustainability and resource conservation. Handmade paper production typically entails less energy consumption and pollution compared to industrial papermaking processes, making it a more environmentally friendly option. Artisans often utilize recycled materials or locally sourced fibers, further reducing the ecological footprint of handmade paper. In contrast, the mass production of machine-made paper relies heavily on virgin pulp from trees, contributing to deforestation, habitat loss, and carbon emissions. Efforts to adopt sustainable practices, such as certification schemes and eco-friendly technologies, are driving positive change within the paper industry.

Conclusion

In conclusion, the distinction between handmade paper and machine-made paper extends beyond mere production methods to encompass a myriad of qualities, characteristics, and applications. While handmade paper embodies tradition, craftsmanship, and artistic expression, machine-made paper epitomizes efficiency, consistency, and utility. Each possesses its own merits and appeals to distinct audiences, reflecting the diverse needs and preferences of consumers. Ultimately, the choice between handmade paper and machine-made paper hinges on factors such as purpose, aesthetics, and sustainability, highlighting the dynamic interplay between tradition and innovation in the realm of papermaking.